Smart manufacturing process

At Willpro we have our own production facilities. In this post we will explain what machinery we have and why we work with a smart manufacturing process. First an overview of our types of machinery, second an explanation of high-mix, low-volume manufacturing. And finally we will explain the benefits of our own developed software.

Deze post in het Nederlands lezen? Klik dan op deze link.

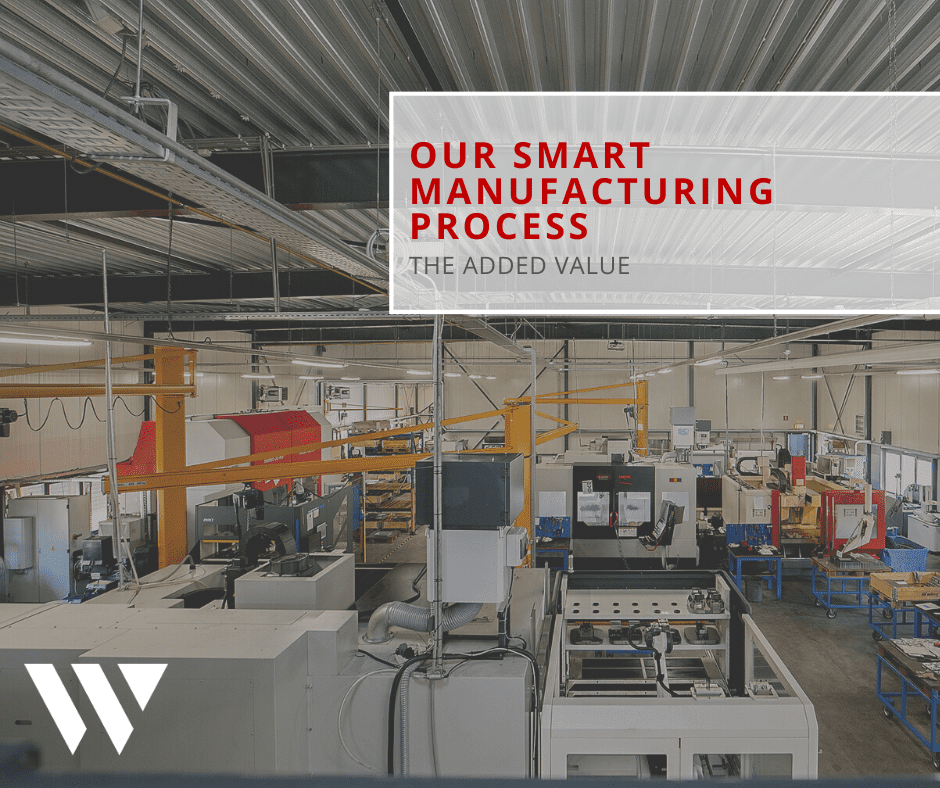

Machines in our production facilities

Our manufacturing process contains 17 metalworking machines and 2 side load robots. The machines we have are:

- 9 CNC-machining centers incl. 5-axis centers | With a maximum of 2 meters

- 5 Grinding machines | With a maximum of 3 meters

- 2 Sawing machines (fully automatic) | With a maximum diameter 400 mm

- 2 Lathes

Two of our machines are equipped with loading robots. These fully automated systems allow an unmanned production for 8 to 16 hours.

Process of manufacturing

The production process is based on a high-mix, low-volume manufacturing. This refers to a large variety of products in small quantities. A typical serie size is 10 to 100 pieces. This means that our machines are setup to quickly switch between the different products, therefore we are flexible and able to respond rapidly to our customers’ requests. For example, all our CNC-machining centers are equipped with zero-point clamping systems. With these systems, you can change the clamping devices within minutes, instead of hours.

Digital manufacturing

Not only the hardware is important in the manufacturing process, the software also has an increasing important role. We use an ERP system of MKG, Solidworks and Edgecam for our CAD/CAM, and a tool management system from Gühring to document all relevant transaction data of our inventory and to monitor the stock levels.

We also developed our own software that is connected to our ERP system, CAD/CAM, and our machines. With this software we can monitor the planning closely and act in time accordingly. This increases the reproducibility of our customers’ machine parts. It documents all the important data settings, so that we can set up the machines instantaneously in case of repetative orders. It reduces the downtime and prevents making mistakes! This is why we call it a smart manufacturing process.

As you can read our whole production process has a lot of added value for our customers. Our machines are ready to process or edit your products! If you need more information or if you want us to produce parts for you, then do not hesitate to contact us!