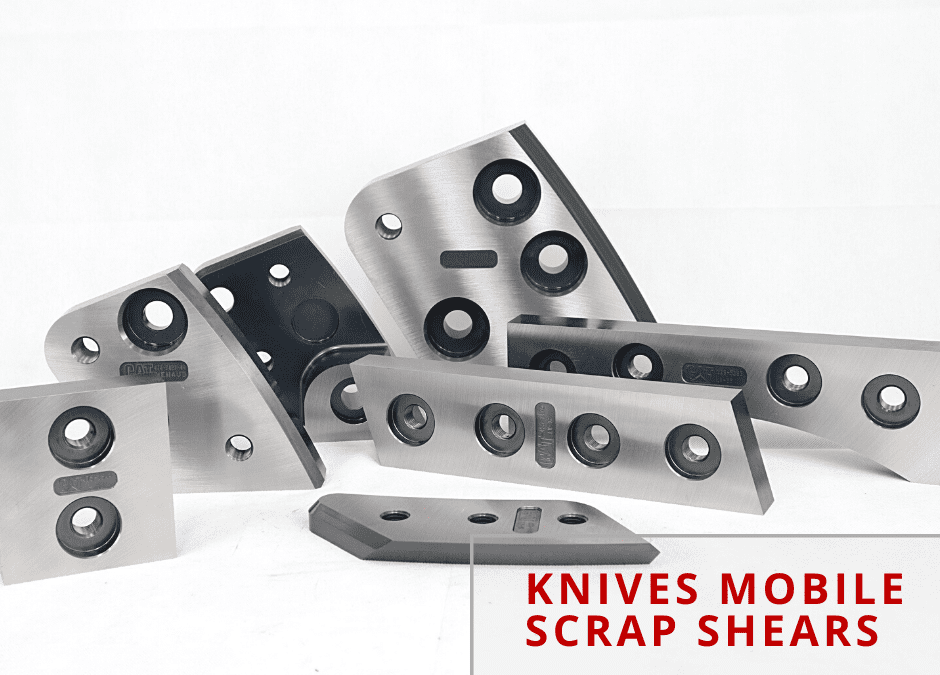

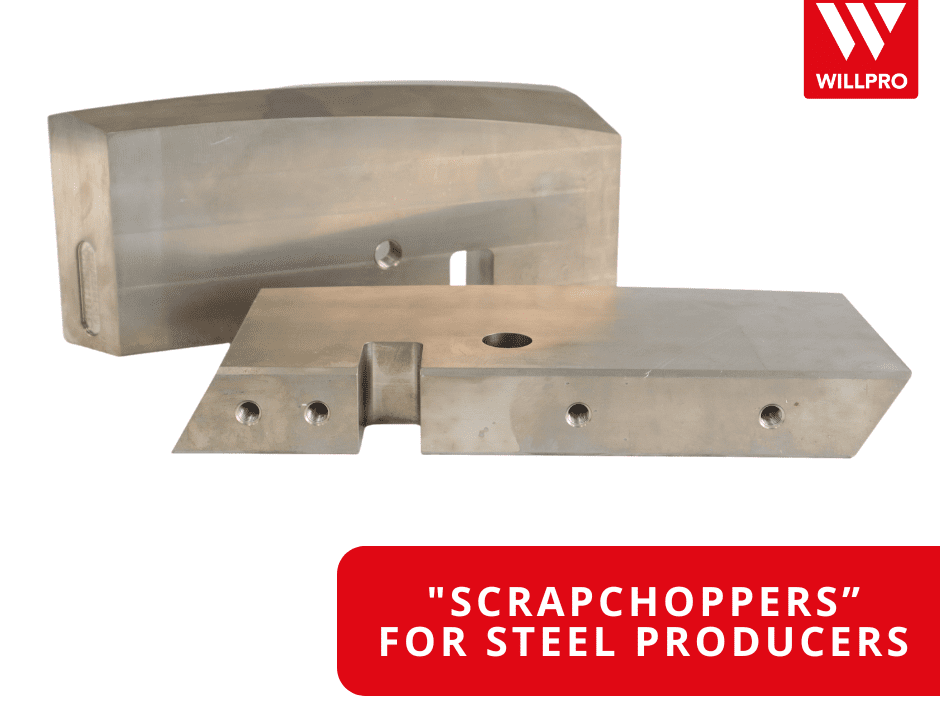

Blades for mobile scrap shears

Willpro produces knives for mobile scrap shears that are used worldwide for the cutting of steel. We produce your knives on basis of the drawings that you provide as a manufacturer of the scrap shears. The high quality of the knives is determined at Willpro by the use of the correct type of material, the exact dimensions and the specific kind of heat treatment. The right knives are important for the quality of your mobile scrap shears. But what are mobile scrap shears and how are the knives produced? You can read that in this article.

Do you want to read this post in Dutch, click on this link.

Mobile scrap shears

Mobile scrap shears are work tools for excavators. They are a necessity to make sure that the excavator is suitable for cutting steel. They come in different shapes and sizes, and are usually classified based on tons of cutting force.

The shears are widely applicable for cutting all kinds of scrap to demolishing buildings with steel structures, and are even used even for cutting whole ships. These machines have to withstand all kinds of environments for example on a construction site with a lot of dust or dealing with extreme temperatures. Due to the enormous cutting force there are high demands on the toughness and wear resistance of the knives.

Production of knives

Material

It is important to use the correct high-quality steel for the production of the knives. In general, 1.2767 wst. and 1.2746 wst. (4% nickel percentage) are used for these products. Willpro has a large stock of this material available in various sizes. This material has a delivery time of approximately 4 to 6 months. That is why the stock of steel is monitored, based on the planned purchase of the customer, to make sure there is always enough available and reordered on time.

Production and heat treatment

Willpro makes its own 3D production drawing for each product, based on the customer drawing. Do you have doubts about handing over these drawings? We only supply manufacturers and always sign a non-disclosure agreement to make sure your drawings are in safe hands.

Based on the 3D production drawing, the material is sawn and processed on the CNC milling machines. Then the knives undergo a heat treatment, this ensures that the products get the correct hardness and wear properties. After this heat treatment, the knives are machined to their final size. This is done by grinding or by CNC milling.

OEM and storage

As an Original Equipment Manufacturer (OEM), we can provide the knives with the logo and characteristics of our customers, so that it fits in with their own manufacturing. After providing the company characteristics and a final check, the knives are stored in our warehouse or delivered directly to the customer.

Delivery times of blades

Other suppliers have a long production time to produce these knives due to the aforementioned delivery time of the material and the complex production process. In order to prevent downtime, or not being able to deliver the mobile scrap shears, we can in consultation, keep these products in stock.

Willpro is your partner for the production of mobile scrap shears. The dimensions of the knives are impeccable and a delivery reliability that you can count on. Do you want to know more? Let us know!

Do you want more information about the qualities that are suited to cut steel? Then, read this article: Materials to cut steel.